The

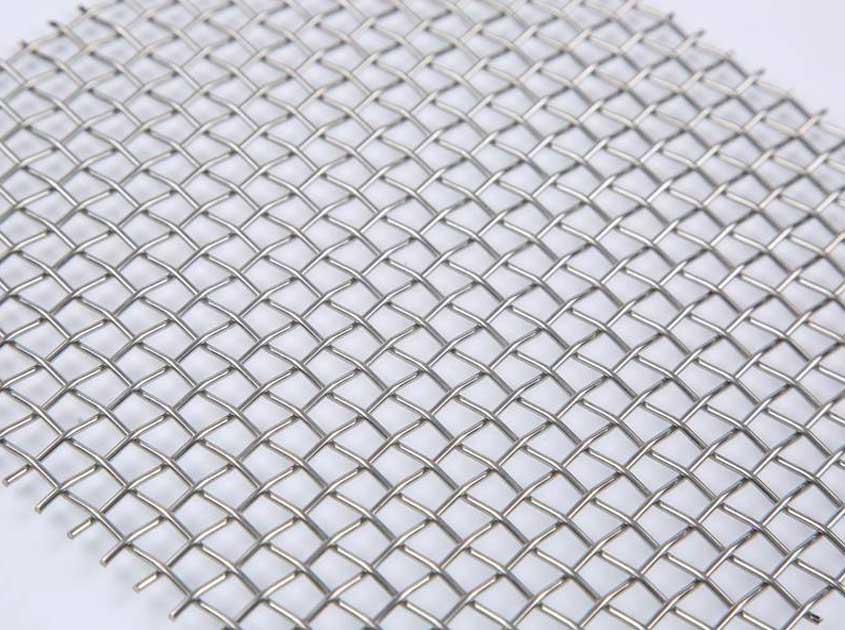

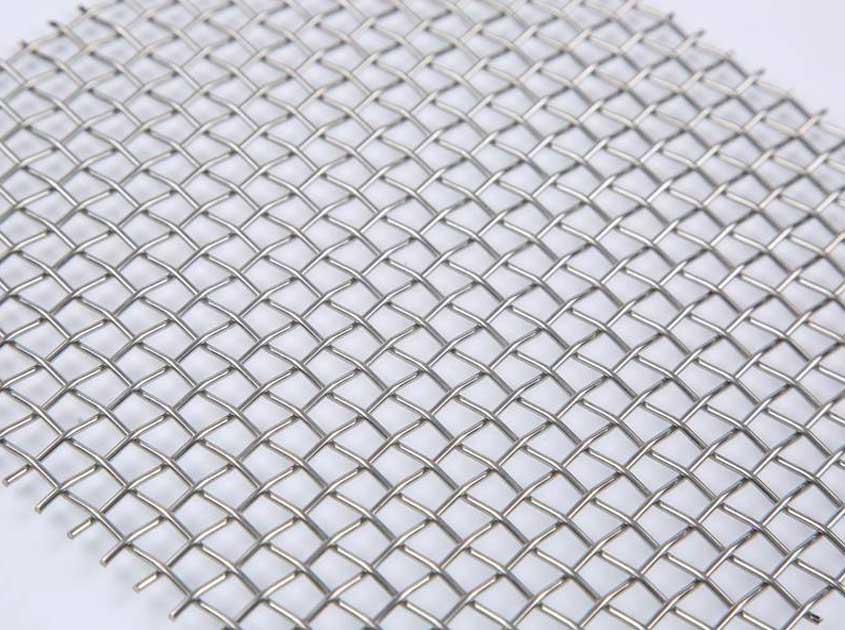

stainless steel wire mesh is made of superior grade stainless steel such as 316 316L 304L 304HC 304 302, etc. It is mostly used for screening and filtering under acid and alkali environmental conditions. It is used as mud mesh in the petroleum industry, chemical fiber industry, as a screen filter, and electroplating. The following describes the weaving method of stainless steel wire mesh

1. Plain weaving: Plain weaving: each warp thread crosses each weft thread up and down, the diameter thread and the weft thread have the same thickness, and the warp thread and the weft thread form a 90-degree angle.

2. Twill weaving: Twill weaving: each warp thread crosses each two weft threads up and down, and each weft thread crosses each two diameter wires up and down.

3. Density weaving: Density nets are also called mat-type nets. The warp and weft have different diameters and different meshes. They are characterized by dense warp and dense weft, thick warp and fine weft. The length direction is the warp and the width direction is the weft.

Dense weave mesh is divided into mat-type mesh plain weave and mat-type mesh twill weave.

(1): Mat mesh twill weaving: each diameter wire crosses each 2 weft wires up and down, and each weft wire crosses each 2 diameter wires up and down.

(2): Double-filament Dutch weaving: This kind of weaving is very similar to the twill Dutch weaving. There are two weft threads, which can be stacked closely with the warp threads. This kind of silk cloth is mostly used to filter micron level filtration.

(3): Five-shed weaving: This kind of weaving warp and weft is not made of monofilament but is woven with several separate wires.

.jpg)

.png)