In the realm of industrial manufacturing, small coil wire plays a pivotal role in a wide array of applications. The production of small coil wire has seen remarkable advancements over the years, driven by technology, sustainability, and evolving market demands. This article explores the latest innovations in small coil wire manufacturing, shedding light on the exciting developments that are shaping this essential industry.

The Evolution of Small Coil Wire Manufacturing

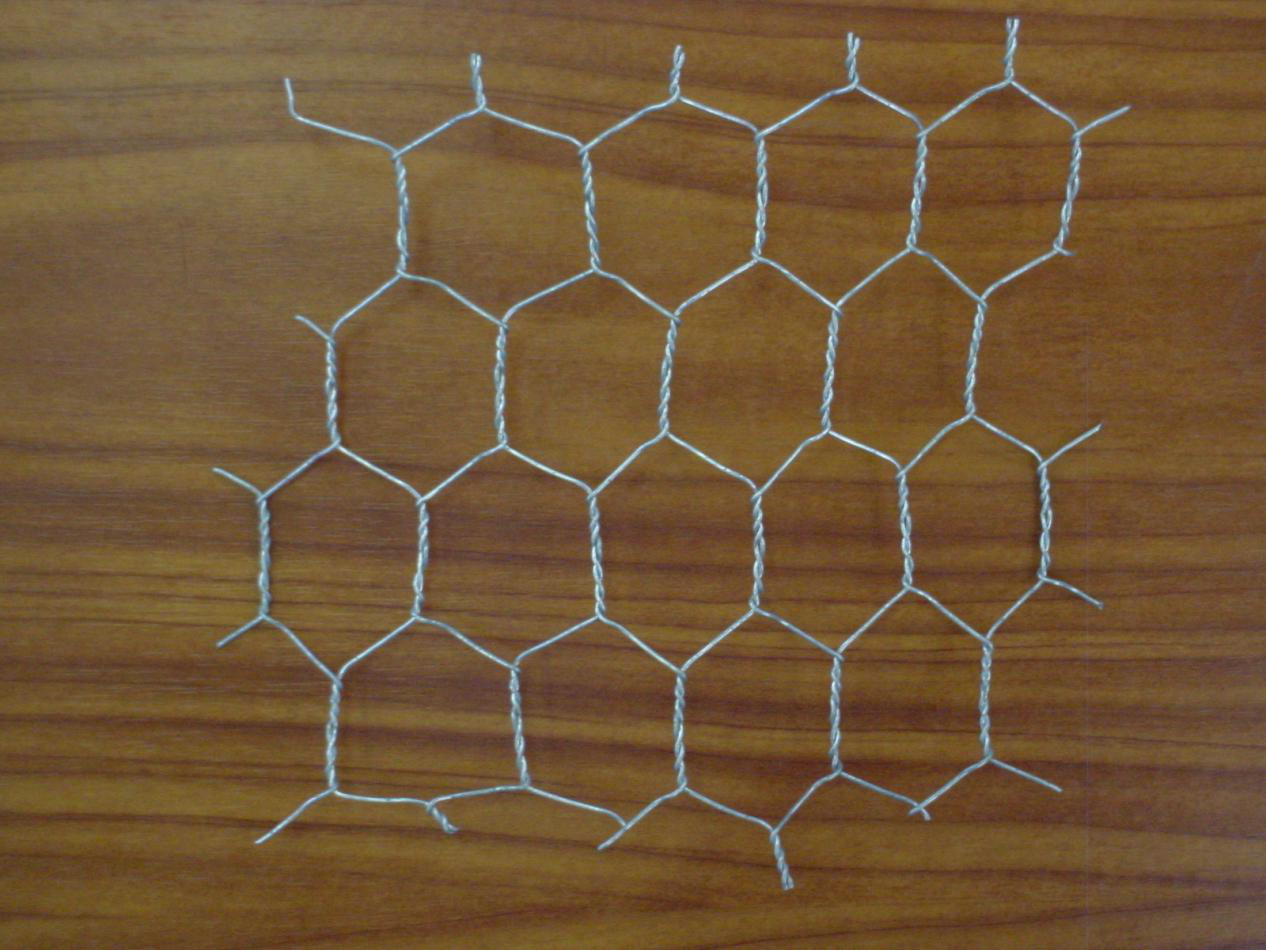

Small coil wire, also known as coil tie wire or baling wire, is a fundamental component used across multiple industries, including construction, agriculture, packaging, and more. Traditionally, the manufacturing process involved basic wire drawing and coiling techniques. However, recent innovations have significantly elevated the efficiency, quality, and sustainability of small coil wire production.

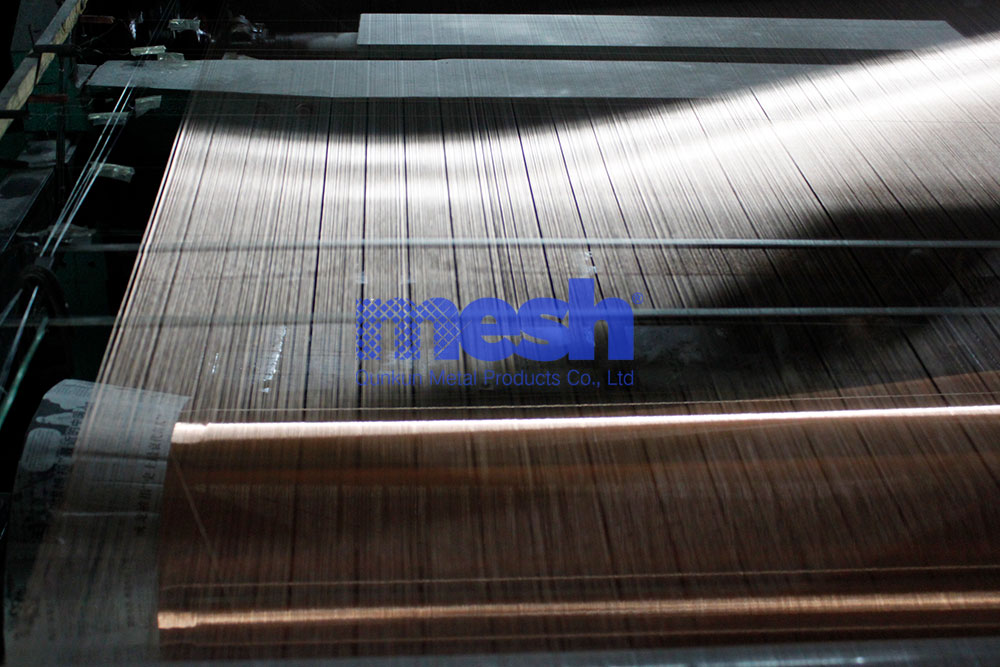

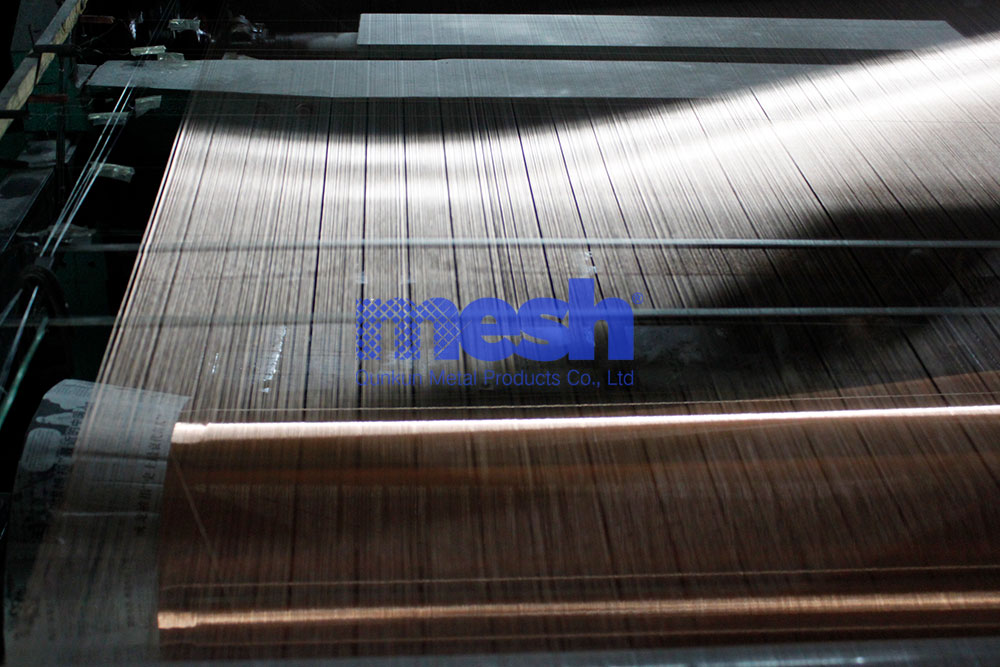

1. Advanced Wire Drawing Technologies:

Modern small coil wire manufacturing employs state-of-the-art wire drawing technologies that ensure precise wire diameter control and consistent quality. These technologies enhance the tensile strength and durability of the wire, making it suitable for a broader range of applications.

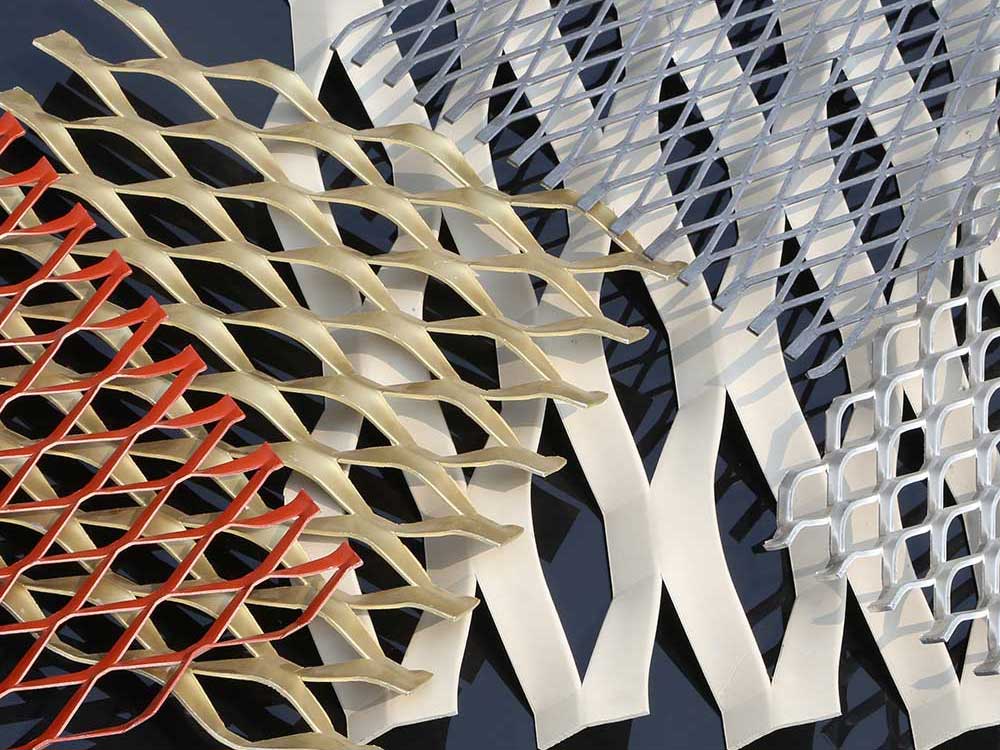

2. Alloy and Material Innovations:

Manufacturers are constantly exploring new alloy compositions and materials to optimize the performance of small coil wire. Utilizing high-quality materials and alloys with specific characteristics, such as corrosion resistance and increased tensile strength, ensures that the wire meets the perse needs of various industries.

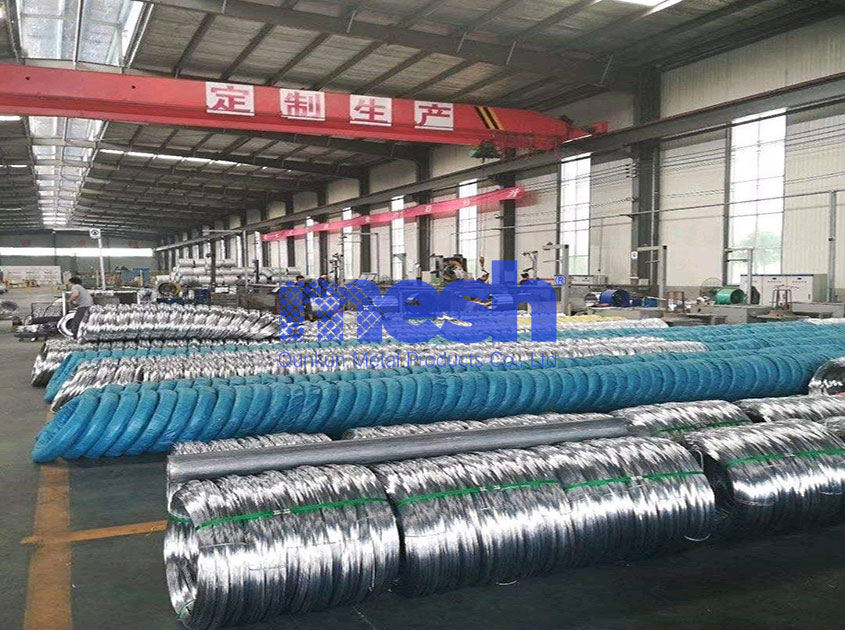

3. Automation and Robotics:

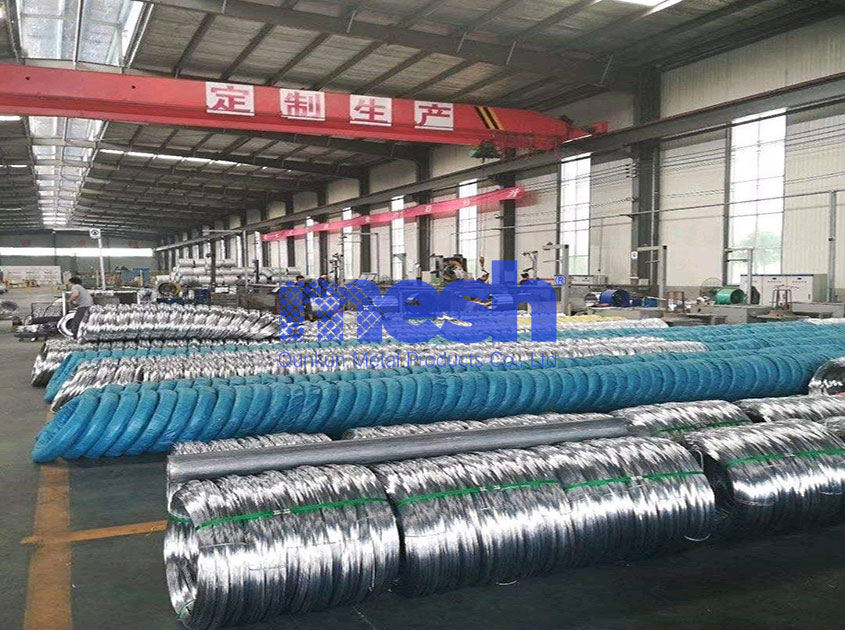

Automation has revolutionized the small coil wire manufacturing process. Automated machinery and robotics are now used for wire drawing, coiling, cutting, and packaging. This not only enhances production speed but also ensures precision and consistency in the final product.

4. Sustainable Manufacturing Practices:

In response to the global shift towards sustainability, small coil wire manufacturers are embracing eco-friendly practices. This includes using recycled materials in production and implementing energy-efficient processes to minimize environmental impact. Sustainable manufacturing practices contribute to a more responsible and greener industry.

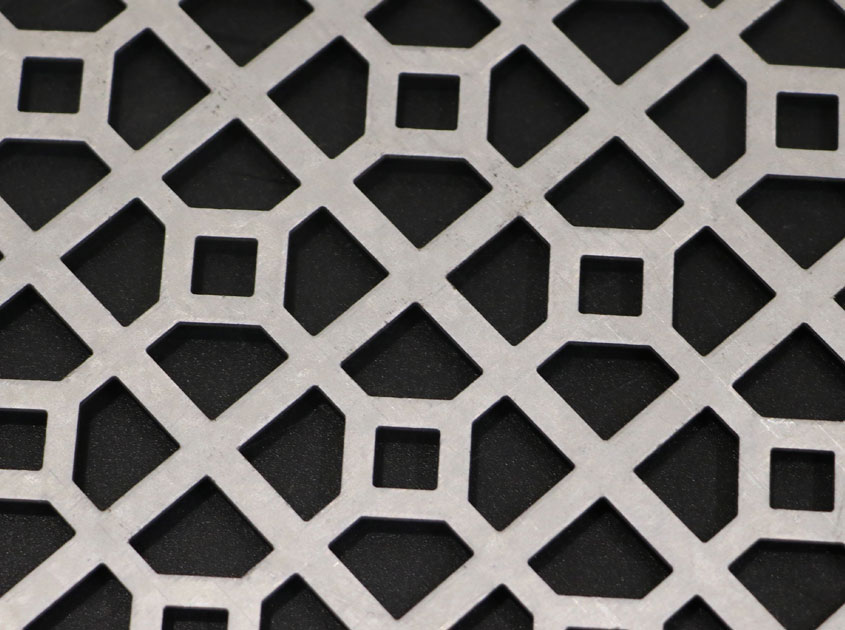

5. Customization and Tailored Solutions:

With advancements in manufacturing technology, small coil wire can now be customized to meet specific industry requirements. Tailored solutions ensure that the wire meets precise specifications, sizes, and finishes, catering to the unique needs of each application.

6. Quality Control and Certification:

Modern small coil wire manufacturing incorporates stringent quality control measures at every stage of production. Industry certifications and compliance with international standards ensure that the wire meets the highest quality benchmarks, providing confidence to end-users and contributing to the reliability of the product.

The Future of Small Coil Wire Manufacturing

As technology continues to advance, the future of small coil wire manufacturing looks promising. Predictive analytics, machine learning, and the integration of Industry 4.0 principles are expected to further streamline production processes, enhance quality, and reduce waste. Additionally, sustainability will remain a focal point, with an emphasis on greener materials and energy-efficient practices.

Conclusion

Innovations in small coil wire manufacturing are shaping the industry, paving the way for enhanced performance, sustainability, and versatility. The integration of advanced technologies and materials showcases a bright future for this critical component, ensuring that small coil wire continues to play a vital role across a myriad of industries. Stay tuned as the industry evolves, driven by a commitment to excellence and a vision for a more sustainable tomorrow.

.jpg)

.png)