2025-11-20

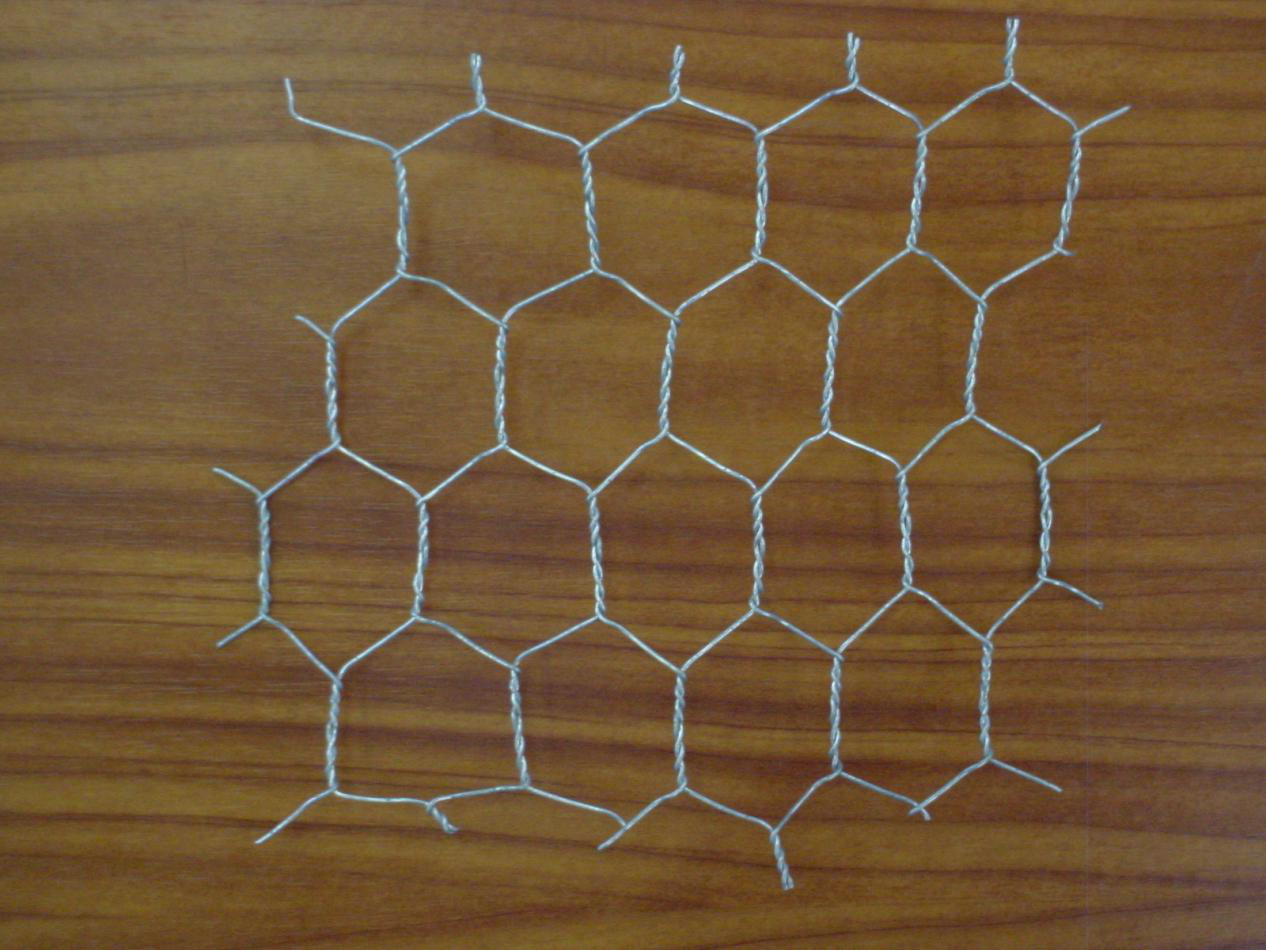

In both the Middle East and South America, demand for wire mesh products continues to grow as the construction, agriculture, mining, and security sectors expand. However, frequent price fluctuations—driven by raw material costs, currency changes, logistics, and market competition—have a significant impact on how distributors plan their procurement strategies.

Understanding these pricing dynamics is crucial for importers who depend on stable supply chains, and it is equally important for Chinese manufacturers aiming to build long-term partnerships. This article analyzes how price volatility affects purchasing decisions and how distributors can navigate these challenges more effectively.

1. What Causes Wire Mesh Price Fluctuations in These Regions?

(1) Raw Material Cost Changes

The prices of steel wire, galvanized steel, stainless steel, and aluminum often fluctuate due to:

Global steel market conditions

Energy cost changes

Mining output

Policy adjustments in producing countries

When material prices rise in China or globally, Middle Eastern and South American distributors face increased import costs.

(2) Exchange Rate Volatility

Currencies in South America—such as ARS (Argentina), BRL (Brazil), and CLP (Chile)—often experience sharp fluctuations.

In the Middle East, USD-pegged currencies are more stable, but fluctuations in euro or yuan can still affect procurement budgets.

(3) Freight and Logistics Costs

Shipping costs can rise due to:

Fuel surcharges

Port congestion

Peak-season container shortages

Longer routes or geopolitical risks

Freight increases indirectly push up landed costs, impacting purchase timing.

(4) Regional Competitiveness

Local market competition—especially from Turkey, India, or local producers—may influence pricing and distributor decisions.

2. How Price Changes Affect Distributors’ Purchasing Behavior

✔ 1. Shift from Spot Purchase to Strategic Stocking

When prices show an upward trend, many distributors prefer:

Placing larger orders

Stocking up before prices rise further

Securing long-term supply agreements

This helps them maintain stable profit margins and secure inventory for high-season demand.

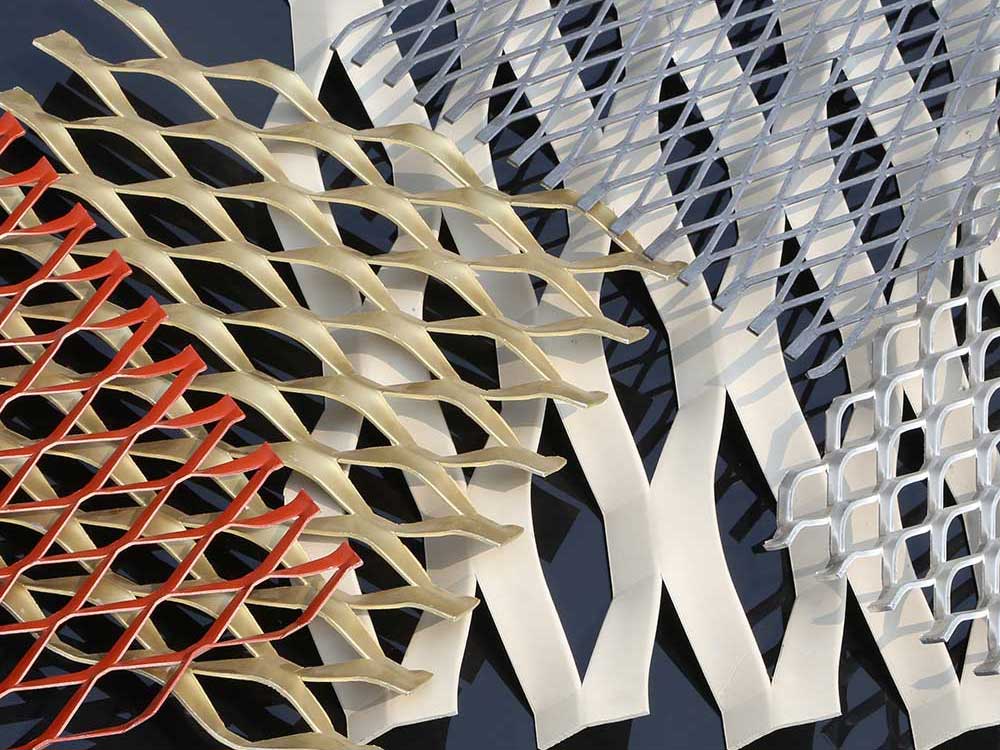

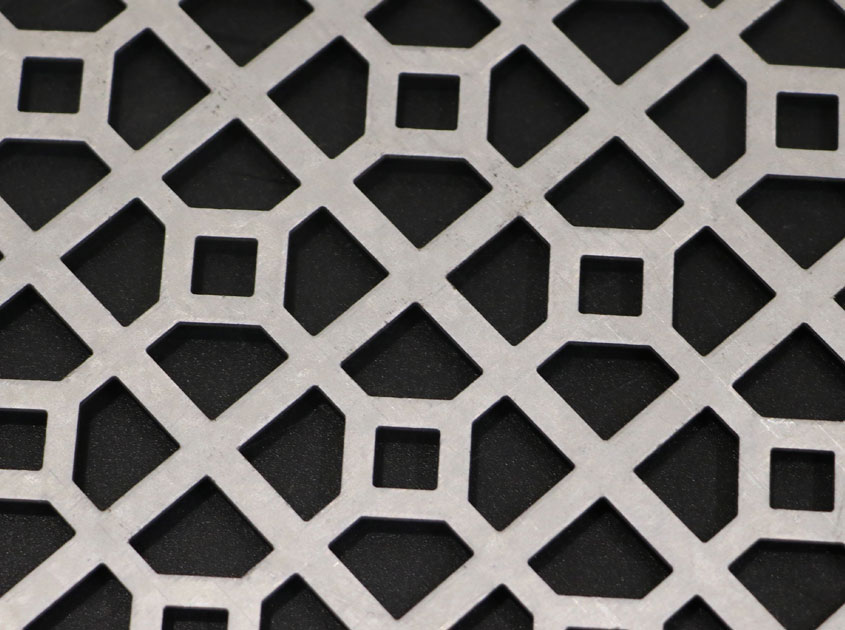

✔ 2. Increased Attention to Cost-Effective Alternatives

For example:

Switching from stainless steel to galvanized mesh

Choosing welded wire mesh rolls instead of panels

Using aluminum mesh for lightweight structures

Distributors become more flexible with specifications to balance quality and price.

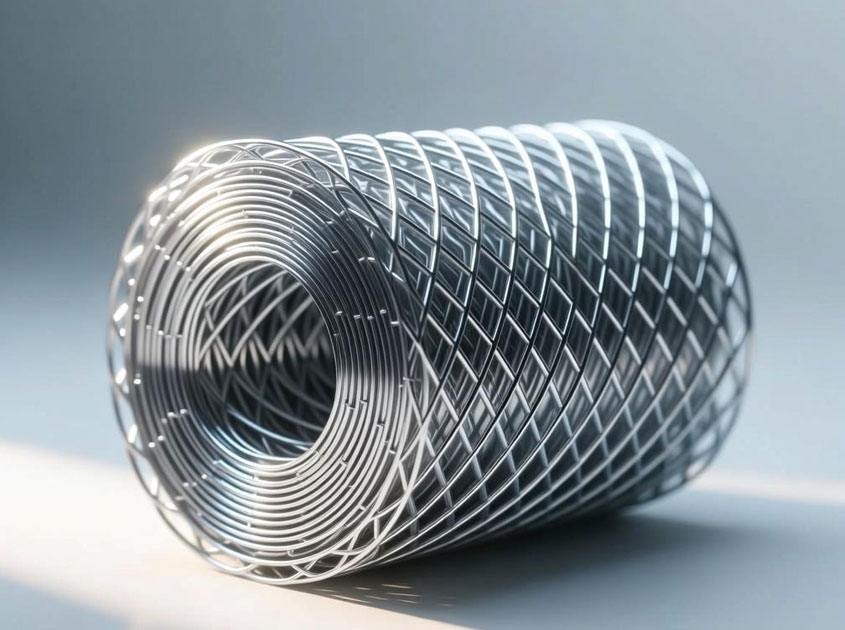

✔ 3. Diversifying Supplier Sources

Price volatility pushes buyers to reduce dependency on one source.

They may:

Add new Chinese suppliers

Compare pricing between China, Turkey, and India

Look for manufacturers with stable material supply chains

However, consistency in quality remains the most important factor.

✔ 4. Slowdown in Purchase During Price Peaks

If prices rise too fast, many importers:

Delay orders

Reduce quantity

Purchase only urgent items

This can extend buying cycles and shift procurement windows.

✔ 5. Increase in Forecast-Based Purchasing

Some key clients—such as mining companies, construction firms, and government contractors—lock in project demand in advance.

This helps distributors plan purchases more accurately.

3. Middle East vs South America: How Each Market Reacts

prev:How to Choose Wire Mesh Products Suitable for the South American Market

next:How South American Distributors Can Expand Their Market by Partnering with Chinese Wire Mesh Manufacturers

.jpg)

.png)