2026-02-03

Welded wire mesh has become one of the most widely used construction materials worldwide. From residential buildings and commercial projects to infrastructure and industrial facilities, welded wire mesh plays a critical role in reinforcing concrete, improving structural stability, and controlling construction costs. Its popularity continues to grow in global markets, especially in developing and fast-growing regions.

This article explains why welded wire mesh is so popular in construction, its key advantages, common applications, and why contractors and developers increasingly rely on it.

1. Strong Structural Performance and Load Distribution

One of the main reasons welded wire mesh is popular in construction is its excellent structural strength.

Welded wire mesh is manufactured by welding steel wires at each intersection, forming a rigid grid structure. This design allows:

Even load distribution across the surface

Reduced cracking in concrete

Improved tensile strength

In concrete reinforcement, welded wire mesh helps prevent shrinkage cracks and enhances long-term durability.

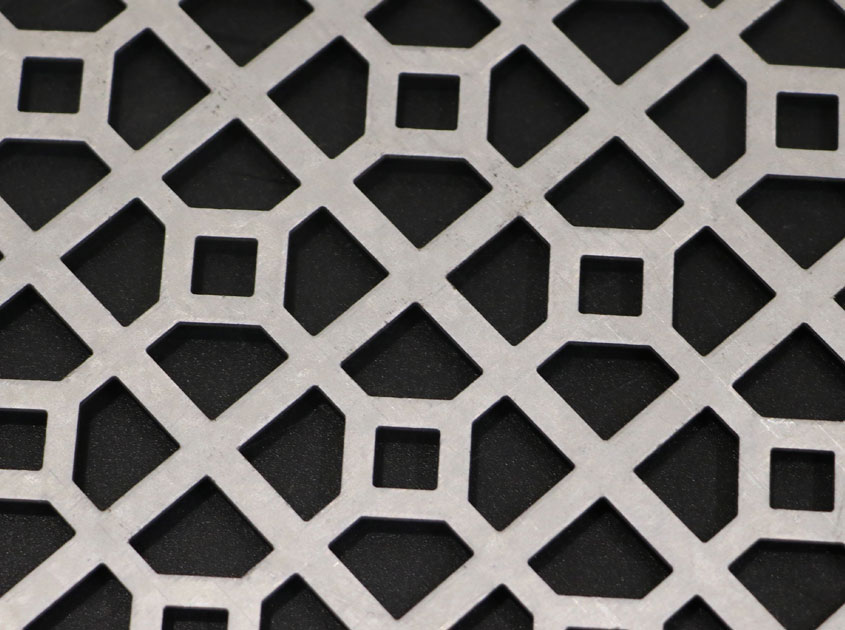

2. Consistent Quality and Precise Specifications

Compared with traditional rebar placement, welded wire mesh offers uniform spacing and consistent wire diameter.

Key benefits include:

Factory-controlled welding quality

Accurate mesh openings

Reliable mechanical performance

This consistency makes it easier for engineers and contractors to meet project specifications and quality standards.

3. Faster Installation and Reduced Labor Costs

Construction efficiency is a major concern for modern projects.

Welded wire mesh:

Is easy to transport and handle

Can be installed quickly on-site

Requires less skilled labor than traditional reinforcement methods

Faster installation directly reduces labor costs and shortens construction timelines, making welded wire mesh an economical choice.

4. Wide Range of Construction Applications

Welded wire mesh is extremely versatile and suitable for many construction scenarios, including:

Concrete slabs and floors

Building foundations

Walls and columns

Pavements and road construction

Precast concrete elements

This versatility makes it a standard material in both residential and commercial construction projects.

5. Cost-Effective Alternative to Traditional Reinforcement

From a cost perspective, welded wire mesh offers an excellent balance between price and performance.

Compared with inpidual steel bars:

Material waste is reduced

Installation time is shorter

Overall project costs are lower

For large-scale construction projects, welded wire mesh provides predictable budgeting and efficient material usage.

6. Compatibility with Modern Construction Standards

Welded wire mesh is designed to comply with international construction standards and engineering requirements.

It is commonly manufactured according to:

ASTM standards

EN standards

ISO specifications

This makes it suitable for global projects and international contractors working across different markets.

7. Improved Concrete Crack Control

Concrete naturally shrinks and expands due to temperature and moisture changes.

Welded wire mesh helps:

Control crack width

Improve surface integrity

Extend service life of concrete structures

This is especially important for floors, slabs, and pavements exposed to environmental stress.

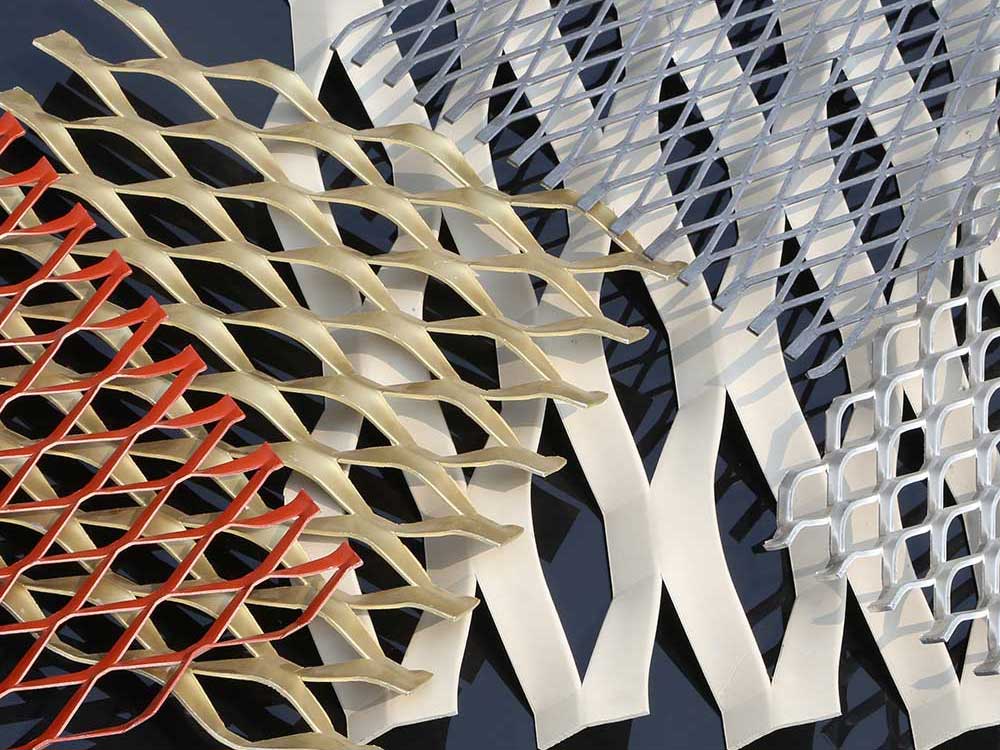

8. Flexible Surface Finishes for Different Environments

Welded wire mesh can be supplied with various surface treatments to match construction conditions.

Common options include:

Black steel welded wire mesh

Galvanized welded wire mesh

PVC coated welded wire mesh

Galvanized and coated versions provide enhanced corrosion resistance for outdoor and humid environments.

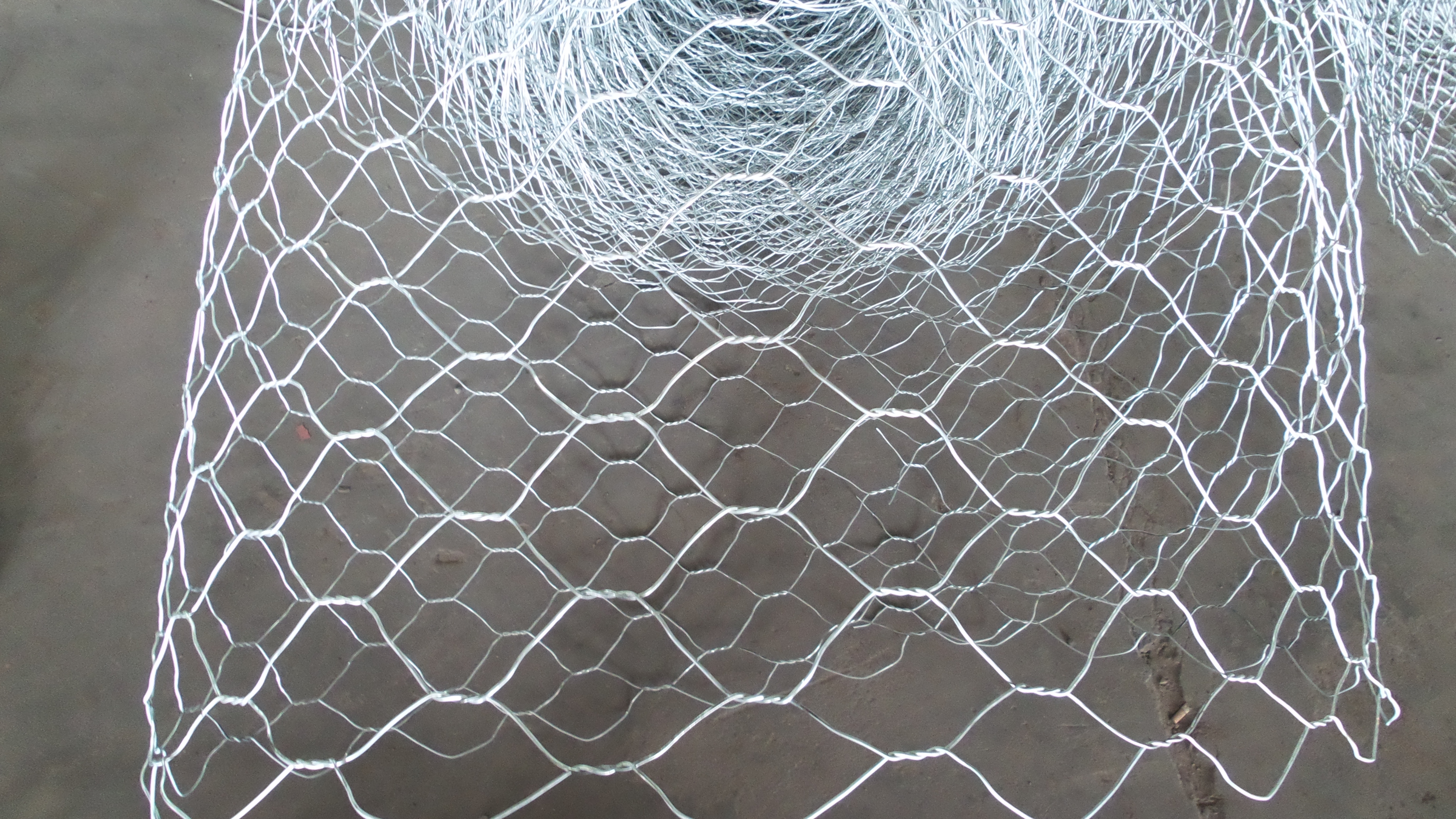

9. Easy Transportation and Storage

Welded wire mesh is available in:

Panels

Rolls

This allows easy stacking, transportation, and storage at construction sites. Efficient logistics further contribute to its popularity in large construction projects.

10. Why Global Contractors Source Welded Wire Mesh from China

China has become one of the world’s leading producers of welded wire mesh.

Key advantages include:

Advanced welding equipment

Stable production capacity

Competitive pricing

Export-oriented packaging solutions

Experienced Chinese manufacturers can supply welded wire mesh tailored to different construction standards and project needs.

Conclusion

Welded wire mesh is popular in construction because it offers strength, consistency, efficiency, and cost-effectiveness. Its ability to reinforce concrete, reduce labor costs, and meet international standards makes it an essential material for modern construction projects.

For contractors, developers, and distributors, choosing high-quality welded wire mesh from a reliable manufacturer ensures better structural performance and long-term value.

prev:What Wire Mesh Types Are Most Popular in South America?

next:none

.jpg)

.png)