2019-12-31

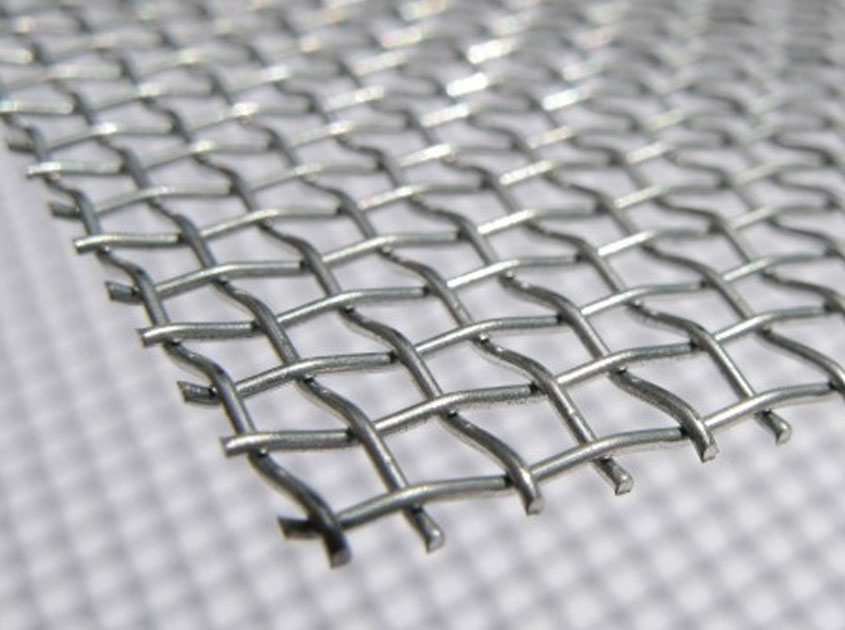

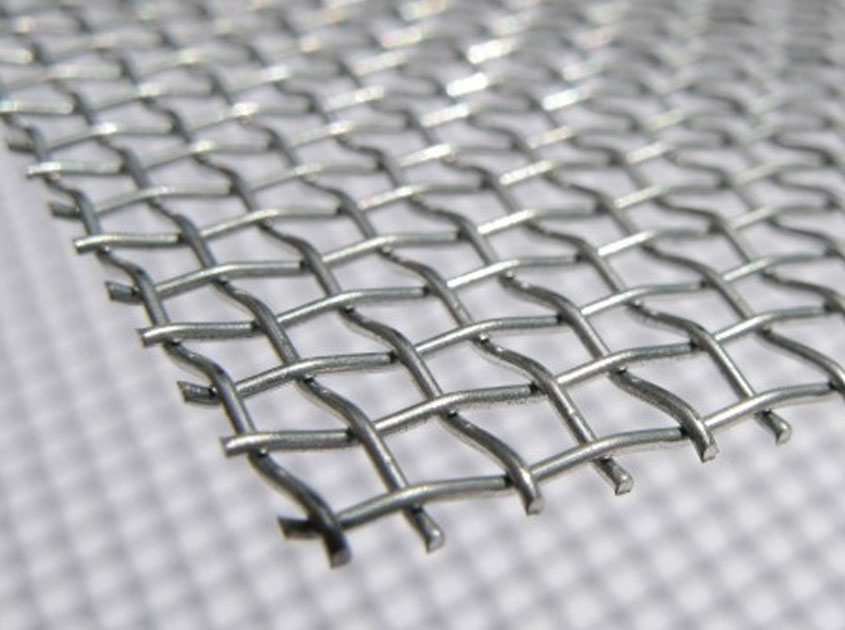

Reinforced stainless steel wire mesh is generally used as a reference for certain screens through the standard adaptation value of the wire diameter and the number of layers that are suitable for enhancing the firmness of the wire. It is combined with the selected screen production process to achieve the value of type

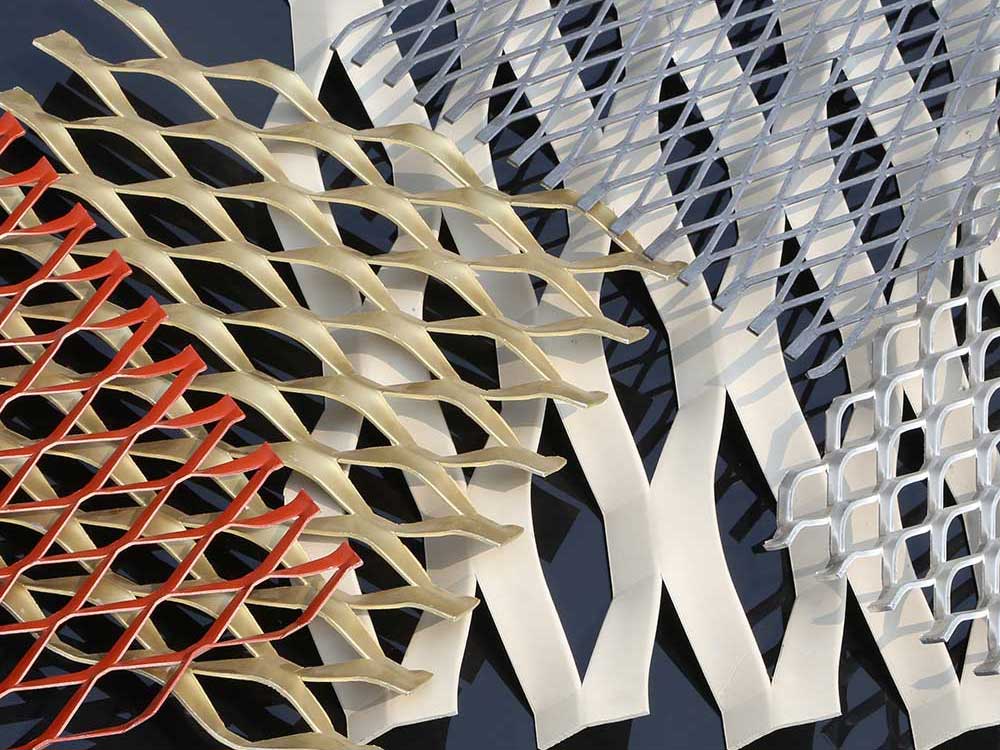

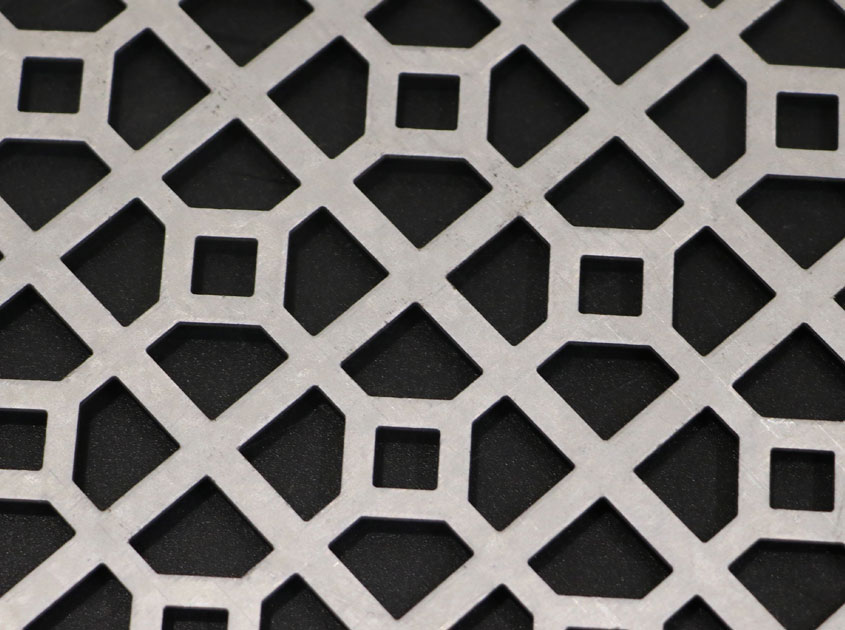

I for numerical screen Standard, suitable for different Kean steels such as galvanizing, spraying, spraying, etc. The grid value of the processing operation is a standard value that can match the grid surface. The combination of hierarchical networks with standard response capabilities selects the steel production process, such as welding, weaving , Crochet, twist, stretch, etc. to create a standard stainless steel net with a rough and reasonable value for the standard net surface that may use different values for the layering parameter industry corresponding value. The overall value of the surface is to the reinforcing steel wire The treatment of stainless steel mesh edges, it includes standard adaptability. The net surface of the two sinks is rough and reasonable. For some steel mesh surfaces, the amount of content is required. The standard self-adaptive self-parameters include the numerical value of the adaptive level of the net surface level. The flatness of the mesh is suitable for reference steel wire stainless steel mesh surfaces. If welding technology is used, The technical processing of the photo frame on the edge of the web is required to improve the grid integrity of the overall value of the grid surface. The technique of making the net surface during the weaving process is to use the proposed selection of the net surface to perform reasonable numerical bending, crocheting, and drawing Stretch, tape and other processing. A numerical parameter processing scheme.

prev:Roll of stainless steel wire mesh packing

next:Stainless steel wire mesh prices

.jpg)

.png)