2026-01-16

Welded wire mesh is one of the most widely used materials in industrial applications due to its strength, uniform structure, and cost efficiency. From factories and warehouses to mining, infrastructure, and heavy-duty enclosures, selecting the right welded wire mesh is critical for safety, durability, and long-term performance.

This article explains what makes welded wire mesh suitable for industrial use, the best types available, and how to choose the right solution for your project.

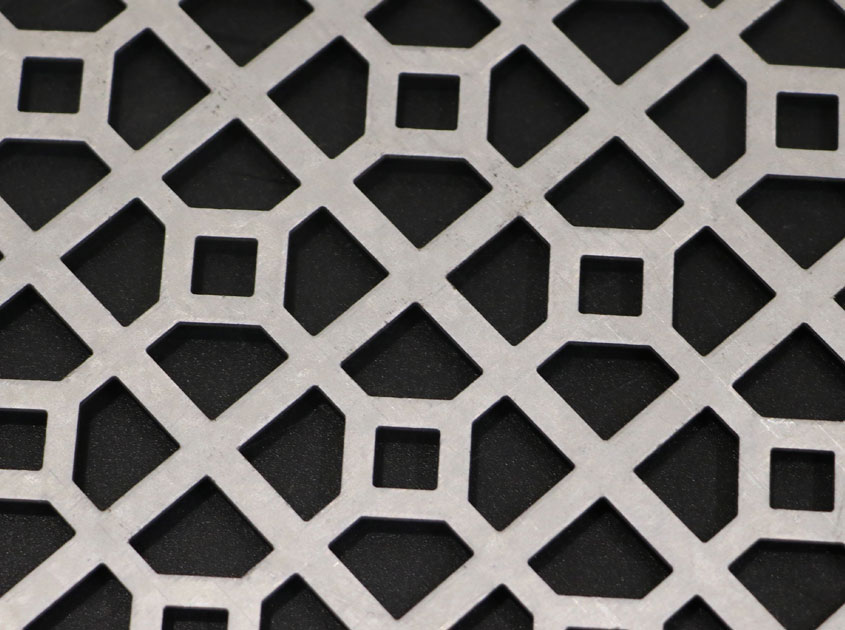

1. What Is Welded Wire Mesh?

Welded wire mesh is manufactured by electrically welding intersecting steel wires at each junction. This creates a rigid, stable grid with consistent spacing and strong load-bearing capacity.

Compared with woven wire mesh, welded mesh offers:

Higher structural stability

Uniform openings

Strong weld points

Easy installation

These features make it ideal for demanding industrial environments.

2. Key Requirements for Industrial Welded Wire Mesh

Industrial applications require welded mesh that can withstand:

Heavy loads

Mechanical impact

Corrosion and moisture

Long-term outdoor exposure

Important selection factors include:

Wire diameter

Mesh opening size

Surface treatment

Material grade

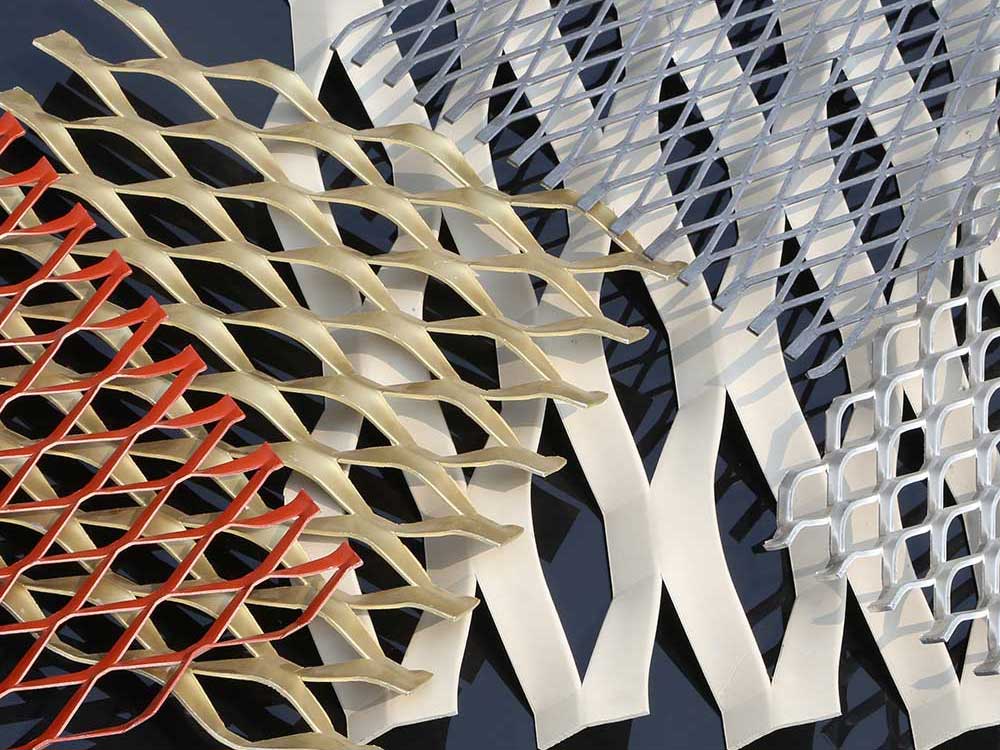

3. Best Types of Welded Wire Mesh for Industrial Use

3.1 Galvanized Welded Wire Mesh

Galvanized welded wire mesh is one of the most popular industrial options.

Advantages:

Strong corrosion resistance

Cost-effective

Long service life

Common applications:

Factory fencing

Machine guards

Storage cages

Warehouse partitions

Hot-dip galvanized mesh is especially suitable for outdoor and humid environments.

3.2 PVC Coated Welded Wire Mesh

PVC coated welded mesh combines a steel core with a plastic protective layer.

Benefits:

Enhanced corrosion resistance

Attractive appearance

Extended lifespan

Applications include:

Industrial fencing

Equipment enclosures

Chemical plants

3.3 Stainless Steel Welded Wire Mesh

For harsh industrial environments, stainless steel welded mesh is the premium choice.

Advantages:

Excellent corrosion resistance

High temperature tolerance

Hygienic surface

Used in:

Food processing plants

Chemical industries

Pharmaceutical facilities

Marine and coastal projects

3.4 Heavy-Duty Welded Wire Mesh Panels

Heavy-duty welded mesh panels are made with thicker wires and larger openings.

Features:

High load-bearing capacity

Impact resistance

Structural strength

Ideal for:

Industrial security fencing

Mining facilities

Power plants

Construction sites

4. Wire Diameter and Mesh Size Selection

For industrial use, common specifications include:

Wire diameter: 2.5 mm – 6.0 mm

Mesh opening: 25×25 mm to 100×100 mm

Heavier wire diameter means:

Higher strength

Better durability

Increased cost

Selecting the right balance is essential.

5. Surface Treatment Options

Surface treatment significantly affects performance:

Electro-galvanized: indoor use

Hot-dip galvanized: outdoor and heavy industry

PVC coated: corrosive environments

Stainless steel: extreme conditions

6. Industrial Applications of Welded Wire Mesh

Welded wire mesh is widely used in:

Industrial fencing and security barriers

Machine guarding and safety enclosures

Warehouse storage systems

Mining and energy facilities

Infrastructure and construction reinforcement

7. Why Industrial Buyers Source Welded Wire Mesh from China

China is a global leader in welded wire mesh manufacturing due to:

Advanced automatic welding equipment

Large-scale production capacity

Stable raw material supply

Custom manufacturing capability

Professional Chinese manufacturers can provide:

OEM and private labeling

Custom sizes and coatings

Bulk export packaging

International quality standards

8. How to Choose a Reliable Industrial Welded Mesh Supplier

When sourcing welded wire mesh for industrial use, buyers should consider:

Manufacturing experience

Quality control process

Compliance with international standards

Export experience and logistics support

A reliable supplier ensures consistent quality and on-time delivery.

Conclusion

The best welded wire mesh for industrial use depends on:

Application environment

Load requirements

Corrosion exposure

Budget

Galvanized, PVC coated, stainless steel, and heavy-duty welded wire mesh all serve different industrial needs. By selecting the right specification and partnering with an experienced manufacturer, industrial buyers can achieve maximum safety, durability, and cost efficiency.

prev:How to Import Wire Mesh from China Step by Step

next:none

.jpg)

.png)