2025-12-15

Choosing the right wire mesh is a critical step for ensuring the success, safety, and durability of any construction, industrial, or architectural project. With a wide range of wire mesh types, materials, and specifications available on the market, buyers often face challenges in selecting the most suitable solution.

As a professional Chinese wire mesh manufacturer with a dedicated international trading website, we help global customers understand how to choose the right wire mesh based on application, performance requirements, and long-term value. This guide will walk you through the key factors to consider before making a purchasing decision.

1. Identify the Application of the Wire Mesh

The first and most important step is to clearly define how the wire mesh will be used. Different applications require different mesh structures and performance characteristics.

Common applications include:

Construction and infrastructure (reinforcement, safety barriers, fencing)

Industrial use (machine guards, storage cages, filtration)

Residential and commercial fencing

Agricultural enclosures (livestock, crop protection)

Architectural and decorative purposes

Understanding the application helps narrow down the suitable mesh type and specifications.

2. Choose the Appropriate Type of Wire Mesh

There are several common wire mesh types, each designed for specific uses:

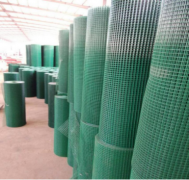

Welded Wire Mesh

Known for strength and rigidity, ideal for fencing, construction reinforcement, and security applications.

Woven Wire Mesh

Offers flexibility and precision, commonly used for filtration, screening, and industrial separation.

Chain Link Mesh

Cost-effective and versatile, widely used for sports fields, industrial perimeters, and temporary fencing.

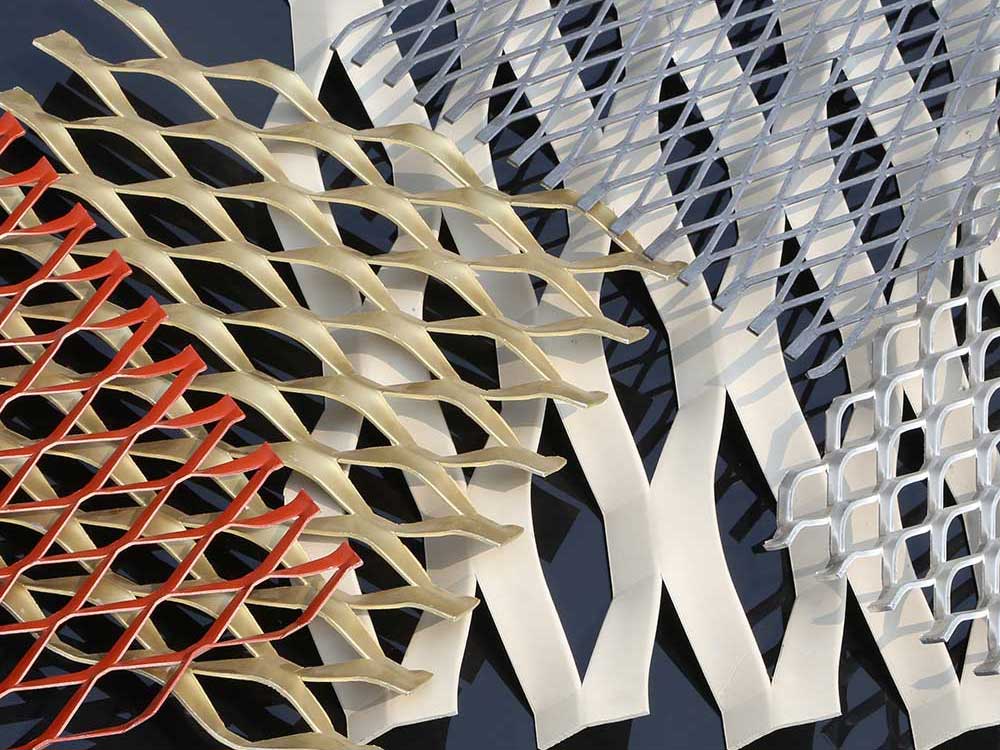

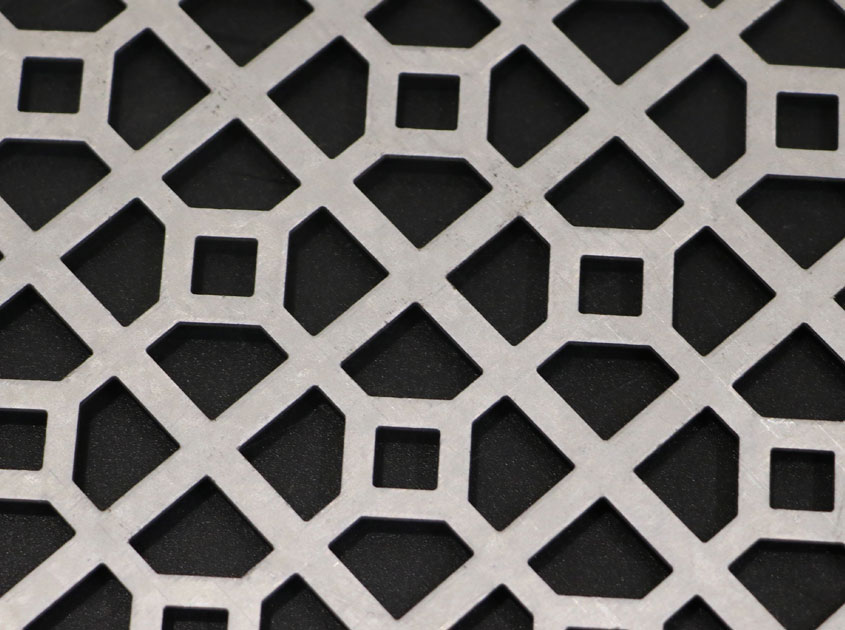

Decorative Wire Mesh

Designed for architectural facades, partitions, and interior design projects where aesthetics matter.

Selecting the right type ensures performance, safety, and cost efficiency.

3. Select the Right Material

Material choice directly impacts durability, corrosion resistance, and lifespan.

Popular options include:

Galvanized steel wire – Excellent corrosion resistance, suitable for outdoor use

Stainless steel (SS304 / SS316) – Ideal for harsh environments, coastal areas, and high-end projects

PVC or powder-coated wire – Enhances durability and visual appeal

Low carbon steel wire – Cost-effective for general applications

For international projects, material selection should also consider climate conditions and local standards.

4. Consider Wire Diameter and Mesh Size

The wire diameter and mesh opening size determine the strength, visibility, and functionality of the wire mesh.

Thicker wire offers higher strength and security

Smaller mesh openings provide better protection and safety

Larger openings reduce material cost and improve visibility

For example, security fencing requires thicker wire and smaller openings, while decorative or agricultural mesh may prioritize flexibility and appearance.

5. Evaluate Strength and Load Requirements

Different projects have different load-bearing needs. Ask the following questions:

Will the mesh need to support weight or impact?

Is it exposed to wind, pressure, or vibration?

Does it require anti-climb or anti-cut performance?

Professional manufacturers can provide technical data and load testing information to ensure the selected mesh meets project requirements.

6. Ensure Compliance with Standards and Regulations

For international projects, compliance is essential. Buyers should confirm that wire mesh products meet:

Local building or safety standards

Industry-specific regulations

Quality inspection and material certification requirements

Working with an experienced China wire mesh manufacturer helps ensure products meet global export and compliance standards.

7. Consider Installation and Maintenance

Ease of installation and long-term maintenance are often overlooked but highly important.

Pre-fabricated panels reduce installation time

Modular designs improve flexibility

Corrosion-resistant coatings minimize maintenance costs

Choosing the right wire mesh can significantly reduce labor and maintenance expenses over time.

8. Balance Price with Long-Term Value

While price is a key factor, the cheapest option is not always the best choice. Buyers should consider:

Product lifespan

Maintenance requirements

Replacement frequency

Supplier reliability and after-sales support

High-quality wire mesh offers better long-term value and reduces operational risks.

9. Choose a Reliable Wire Mesh Manufacturer

The supplier plays a crucial role in project success. A reliable manufacturer should offer:

Stable production capacity

Customization options

Quality control and inspection reports

Professional export experience

Responsive communication and technical support

Chinese wire mesh manufacturers with strong international experience can provide competitive pricing, consistent quality, and reliable delivery.

Conclusion

Choosing the right wire mesh requires careful consideration of application, mesh type, material, specifications, strength, standards, and supplier reliability. By understanding these factors, buyers can select wire mesh solutions that deliver safety, durability, and long-term value.

Partnering with a professional Chinese wire mesh manufacturer ensures access to a wide range of high-quality, customizable, and cost-effective wire mesh products for construction, industrial, agricultural, and architectural projects worldwide.

prev:How Middle East Distributors Can Stand Out in the Competitive Wire Mesh Market

next:What Certifications Should Wire Mesh Products Have?

.jpg)

.png)