Email: sales@qunkun.net |

TEL: +86 180 3242 3029

-

WIRE MESH WIRE NETTING

- WIRES AND NAILS

- FILTERS

-

SPECIAL ALLOY WIRE CLOTH

-

-

Plain Weaved Stainless Steel Wire Mesh

-

Duplex Stainless Steel Wire Mesh UNS 2304

-

Duplex Stainless Steel Wire Mesh UNS S31803(S32205)

.jpg)

-

Super Duplex Stainless Steel Wire Mesh UNS 32750

-

Dutch Weave Stainless Steel Wire Mesh

-

Reverse Dutch Weave Stainless Steel Wire Mesh

-

Twill Weaved Stainless Steel Wire Mesh

-

-

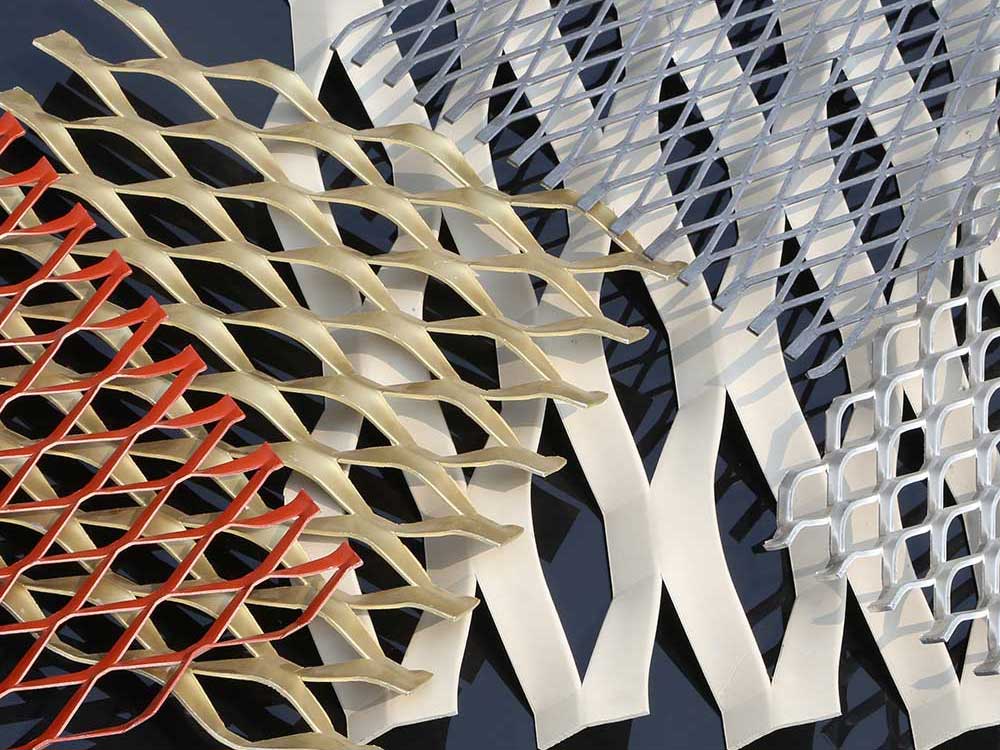

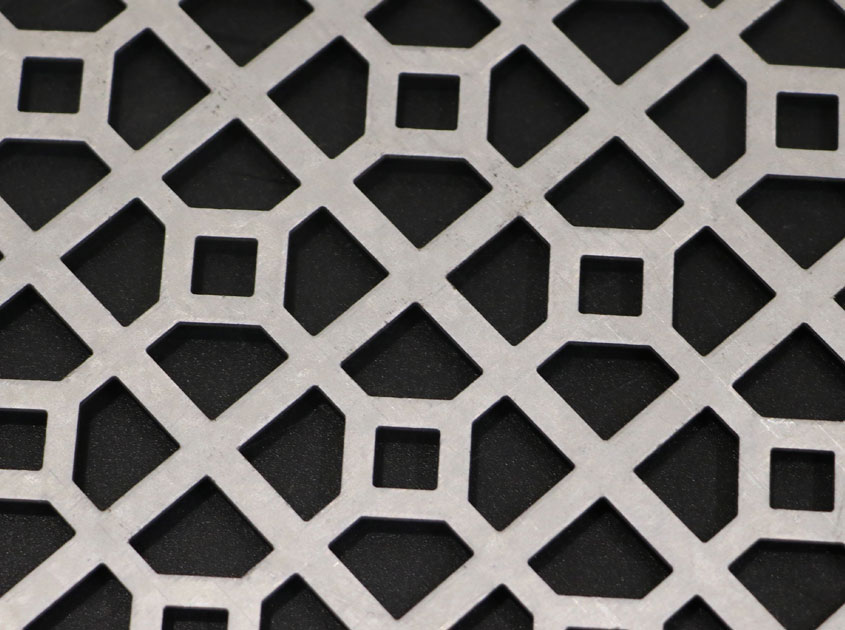

- DECORATIVE MESH

-

FENCING SYSTEMS

-

CHICKEN CAGE AND EQUIPMENT

- EXPANDED AND PERFORATED

.png)