2026-02-10

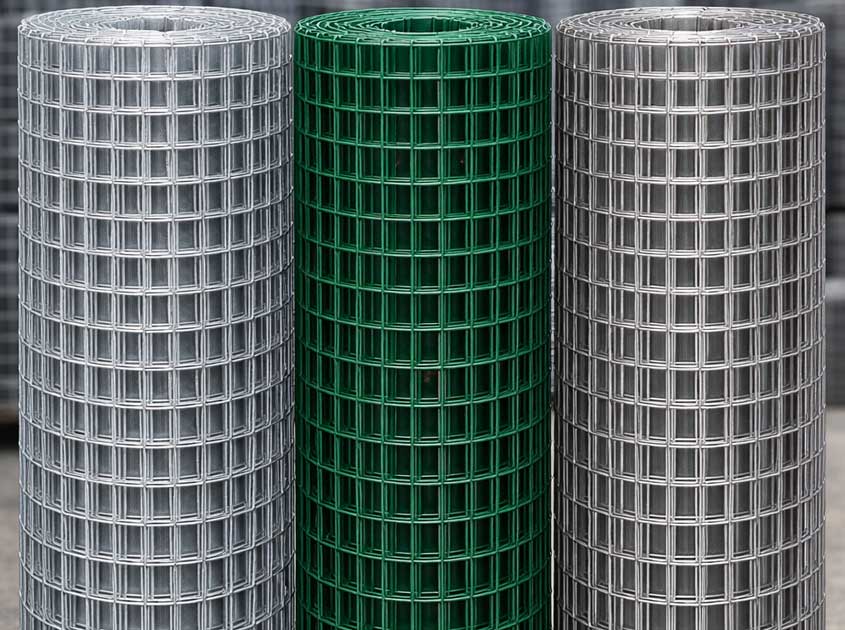

Welded wire mesh has become an essential material in modern construction projects across the Middle East. Known for its strength, durability, and ease of installation, it is widely used in concrete reinforcement, fencing, partitions, and architectural applications. For international buyers, sourcing high-quality welded wire mesh from reliable Chinese manufacturers ensures compliance with local standards and long-term project success.

This article explores the advantages, applications, and specifications of welded wire mesh for Middle East construction projects and provides guidance for buyers looking to source from professional manufacturers.

1. Why Welded Wire Mesh Is Ideal for Middle East Construction

The Middle East presents unique construction challenges, including high temperatures, arid climates, and exposure to UV radiation. Welded wire mesh is preferred because:

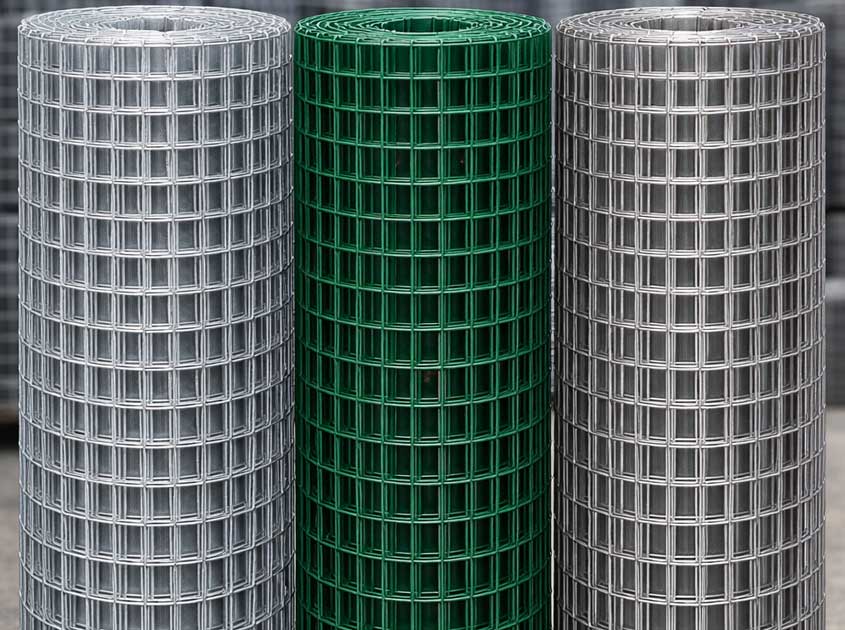

Durability: Galvanized or PVC-coated welded wire mesh resists corrosion, even in harsh desert environments.

Structural Strength: The welded joints provide high load-bearing capacity, making it ideal for reinforced concrete, foundations, and flooring.

Ease of Installation: Pre-fabricated mesh panels reduce labor costs and installation time.

Consistency: Uniform grid patterns ensure even load distribution and high-quality structural performance.

These advantages make welded wire mesh a reliable choice for residential, commercial, and infrastructure projects in the Middle East.

2. Common Applications in Middle Eastern Construction Projects

Welded wire mesh has a wide range of applications in the region:

Concrete Reinforcement: Used in slabs, beams, walls, and foundations to improve tensile strength and prevent cracking.

Fencing and Security: Ideal for construction site fences, perimeter security, and industrial barriers.

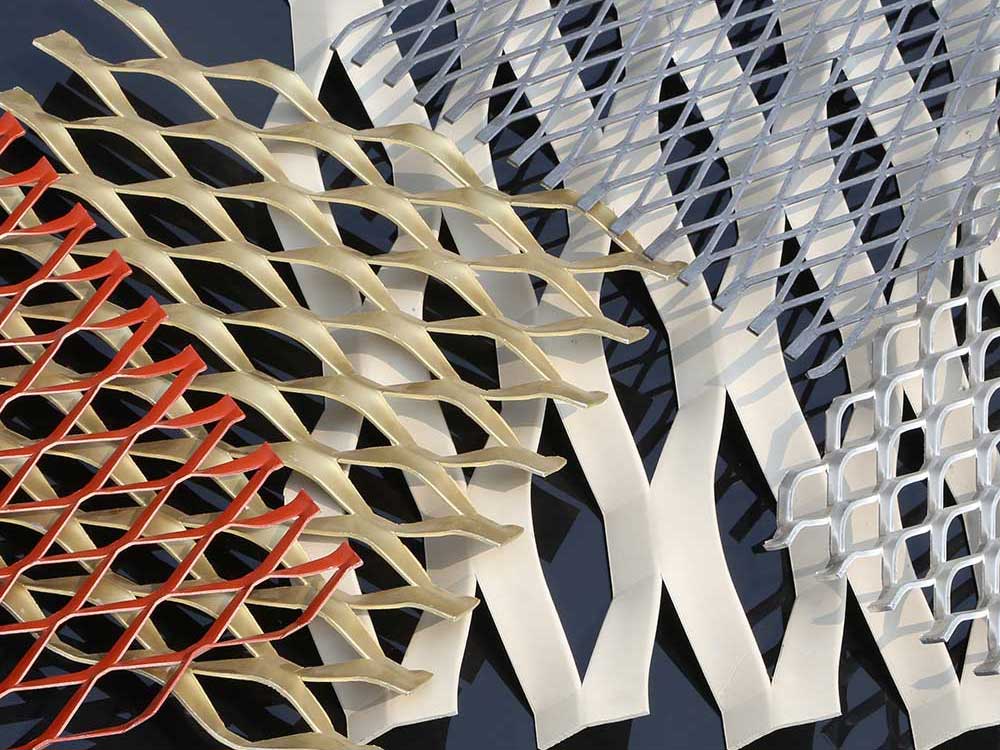

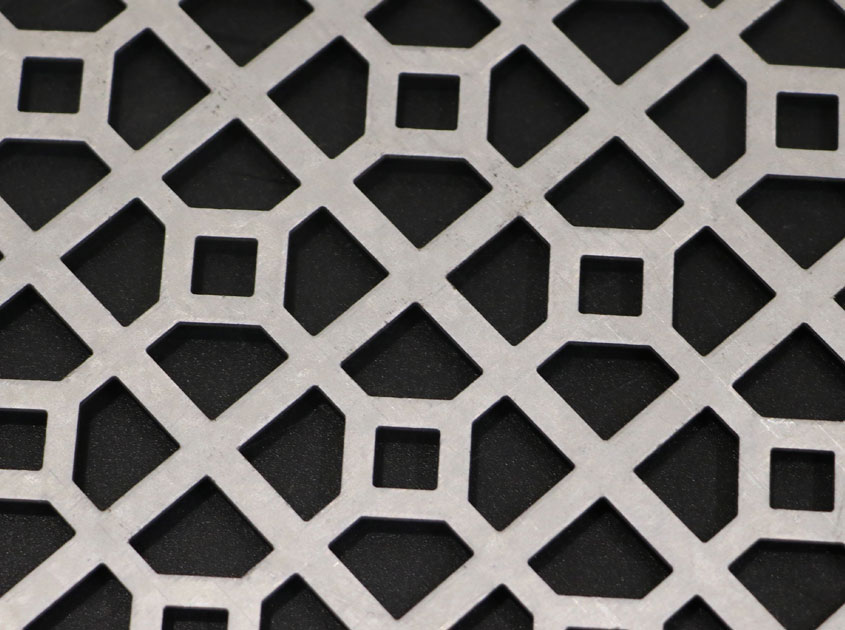

Partition Walls and Ceilings: Architectural welded mesh can serve as partitions or decorative ceilings while maintaining strength.

Infrastructure Projects: Roads, bridges, and tunnels frequently use welded wire mesh for reinforcement.

By choosing the right specifications, buyers can adapt welded wire mesh to both functional and decorative construction needs.

3. Recommended Specifications for Middle East Projects

When sourcing welded wire mesh for the Middle East, several factors should be considered:

Material Type:

Galvanized Steel: Provides corrosion resistance in humid or sandy environments.

Stainless Steel: Suitable for high-end projects requiring long-term durability and minimal maintenance.

PVC-Coated Mesh: Offers extra protection against corrosion and UV exposure.

Wire Diameter: Typically ranges from 3mm to 12mm, depending on load requirements. Heavier diameters are used for structural reinforcement, while lighter gauges serve fencing or partition purposes.

Mesh Size (Opening): Standard sizes include 50x50mm, 100x100mm, or 150x150mm, but custom specifications can be requested to meet local engineering standards.

Panel Size: Common panel dimensions are 2m x 3m or 2m x 6m, but manufacturers can provide cut-to-size solutions for specific project needs.

4. Ensuring Quality and Compliance

Middle East construction projects often require compliance with local building codes and international standards. Buyers should ensure that:

The mesh is manufactured using ISO-certified processes.

Material certificates are provided for steel grade and coating thickness.

Pre-shipment inspections or third-party testing are available to verify durability and dimensions.

Working with experienced Chinese manufacturers helps guarantee consistent quality and adherence to regulatory requirements.

5. Advantages of Sourcing from Chinese Manufacturers

China is a global leader in welded wire mesh production, offering:

Competitive Pricing: Cost-effective solutions for bulk orders.

Custom Manufacturing: Ability to produce panels in various wire diameters, mesh sizes, and coatings.

Technical Support: Guidance on choosing the right mesh for specific construction applications.

Export Experience: Manufacturers familiar with Middle East customs, shipping logistics, and packaging requirements.

By partnering with a reliable supplier, buyers can reduce project delays, minimize defects, and ensure smooth installation.

6. Packaging and Shipping Considerations

For long-distance shipments to the Middle East, proper packaging is critical:

Panel Protection: Each mesh panel should be wrapped with waterproof materials to prevent rust.

Stacking and Strapping: Panels are stacked on pallets or crates and tightly secured to prevent movement.

Container Optimization: Efficient packing ensures maximum container utilization and reduces shipping costs.

Professional manufacturers often provide detailed packing plans to ensure safe delivery.

Conclusion

Welded wire mesh is a versatile and reliable material for construction projects in the Middle East. By selecting high-quality, corrosion-resistant mesh from experienced Chinese manufacturers, buyers can ensure:

Structural integrity for reinforced concrete applications

Durability against harsh environmental conditions

Ease of installation and project efficiency

Compliance with local construction standards

At qunkun metal, we provide a full range of welded wire mesh solutions for Middle East construction projects. From material selection and custom sizes to technical support and export logistics, we help international clients complete projects efficiently and reliably.

prev:Why Welded Wire Mesh Is Popular in Construction

next:none

.jpg)

.png)