2026-01-12

In modern construction, welded wire mesh has become one of the most essential building materials worldwide. From residential housing to large infrastructure projects, it plays a critical role in reinforcing concrete, improving safety, and increasing structural durability.

As a professional wire mesh manufacturer in China supplying global construction markets, we provide welded wire mesh to contractors, developers, and distributors across the Middle East, Europe, South America, Africa, and Southeast Asia. This article explains exactly how welded wire mesh is used in construction, why it is so important, and how to select the right type for your project.

What Is Welded Wire Mesh?

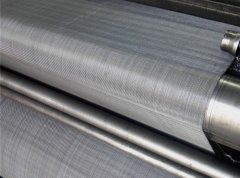

Welded wire mesh is a grid made by welding steel wires at every intersection, forming a strong, rigid panel or roll. Unlike woven mesh, welded mesh does not shift, unravel, or deform under load.

It is usually manufactured from:

Low carbon steel wire

Galvanized steel wire

Stainless steel wire

Common forms:

Welded wire mesh panels

Welded wire mesh rolls

Why Is Welded Wire Mesh Important in Construction?

Concrete is strong under compression but weak under tension. Welded wire mesh acts as reinforcement, preventing cracks, spreading loads evenly, and improving overall structural stability.

In construction projects, welded wire mesh provides:

Crack control

Load distribution

Improved structural integrity

Longer service life

Reduced maintenance cost

These benefits make welded wire mesh a standard material in global building codes and engineering designs.

Main Uses of Welded Wire Mesh in Construction

1. Concrete Slabs and Floors

One of the most common uses is in concrete slab reinforcement.

Welded wire mesh is placed inside:

House floors

Warehouse floors

Parking lots

Industrial floors

It helps:

Prevent shrinkage cracks

Control thermal expansion

Increase load-bearing capacity

This is especially important in hot climates like the Middle East, where temperature changes cause concrete to expand and contract.

2. Walls and Structural Reinforcement

Welded mesh is widely used in:

Load-bearing walls

Partition walls

Retaining walls

Basement walls

It reinforces:

Concrete walls

Block walls

Shotcrete structures

This improves resistance to:

Earth pressure

Wind loads

Seismic activity

3. Road, Bridge, and Infrastructure Projects

In highways, bridges, and tunnels, welded wire mesh is used for:

Road base reinforcement

Concrete pavement

Bridge decks

Drainage channels

It improves:

Fatigue resistance

Load transfer

Long-term durability

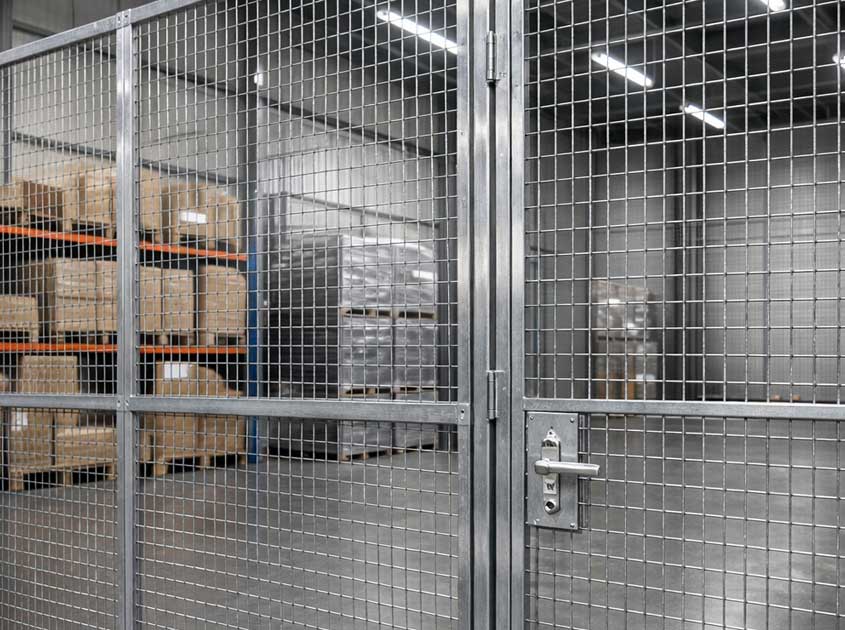

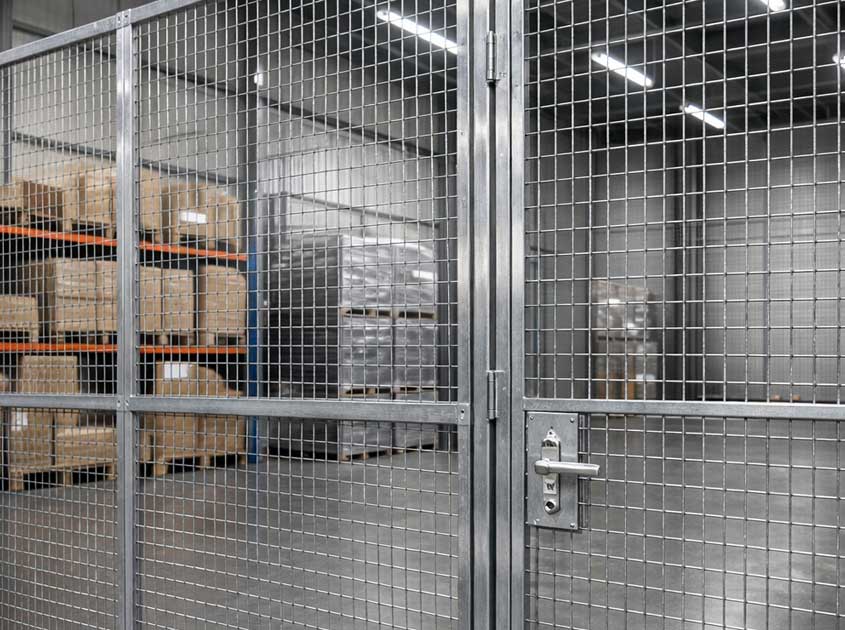

4. Fencing and Site Protection

Welded wire mesh is widely used for:

Construction site fencing

Temporary barriers

Safety enclosures

Equipment protection

Galvanized welded mesh provides:

Rust resistance

High strength

Low maintenance

5. Plastering and Rendering Support

In many regions, welded wire mesh is embedded in:

Plaster

Cement render

Stucco walls

It prevents:

Cracking

Delamination

Surface deformation

This is especially important for high-rise buildings and exterior walls.

Why Welded Wire Mesh Is Better Than Traditional Rebar in Many Applications

Feature Welded Wire Mesh Traditional Rebar

Installation Fast, easy Slow, labor-intensive

Crack control Excellent Limited

Cost Lower Higher

Labor Minimal High

Structural consistency High Depends on installation

For slabs, pavements, and walls, welded mesh often provides better performance at lower total cost.

Choosing the Right Welded Wire Mesh for Construction

To get the best performance, you must select the right mesh.

1. Wire Diameter

Thicker wire = higher strength

Common sizes: 3mm – 8mm

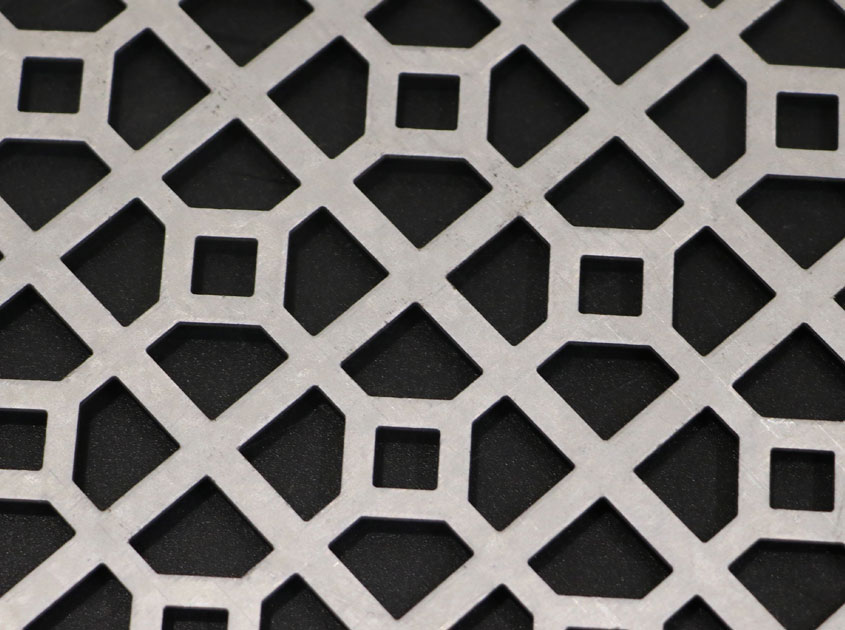

2. Mesh Opening

Smaller openings = better crack control

Typical sizes:

50×50 mm

100×100 mm

150×150 mm

200×200 mm

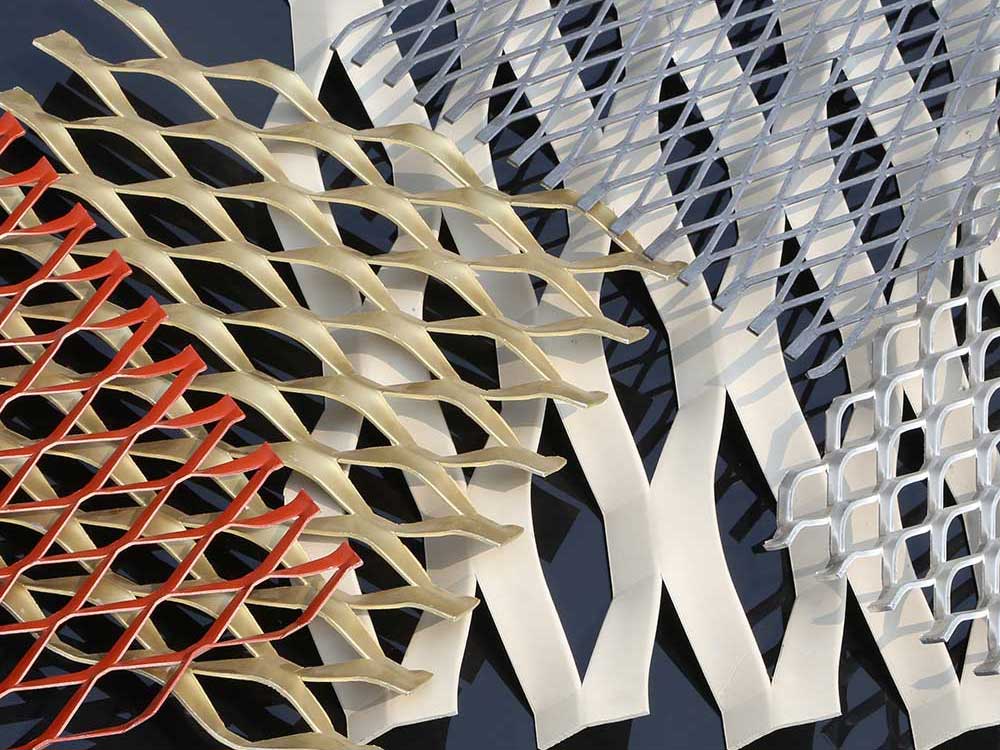

3. Surface Treatment

For harsh environments:

Hot-dip galvanized

PVC coated

Stainless steel

These are ideal for:

Middle East climate

Coastal projects

Outdoor structures

Why Middle East Construction Projects Prefer Welded Wire Mesh

In regions like UAE, Saudi Arabia, Qatar, and Oman, welded wire mesh is favored because:

It resists corrosion and heat

It performs well in sand, humidity, and salt air

It reduces construction time

It improves long-term structural safety

Why Buy Welded Wire Mesh from a Professional Chinese Manufacturer?

China is the world’s largest producer of construction wire mesh, offering:

Large production capacity

International quality standards

Competitive pricing

Custom mesh specifications

Reliable export packaging

As an experienced wire mesh exporter, we provide:

ISO certified production

Custom sizes and coatings

Strong export packing

Stable supply for large projects

Conclusion

Welded wire mesh is one of the most important materials in modern construction. It is used in floors, walls, roads, fences, and structural reinforcement, providing strength, safety, and durability at a cost-effective price.

For developers, contractors, and distributors, choosing the right welded wire mesh—and the right manufacturer—can significantly improve project quality and profitability.

If you are sourcing welded wire mesh for construction, working with a professional Chinese manufacturer ensures you get reliable quality, competitive prices, and global-standard performance.

prev:What Wire Mesh Products Are Suitable for the Middle East Market?

next:How to Import Wire Mesh from China Step by Step

.jpg)

.png)